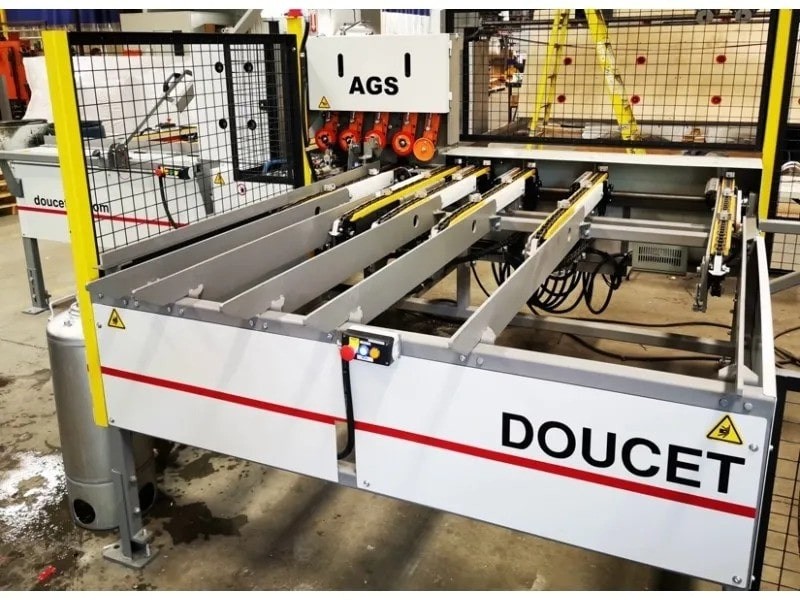

To increase efficiency and safely handle large parts without requiring several employees, Doucet offers a combination of the ALYX — Automated Loader and the AGS — Automatic Gluing System.

This equipment will ensure that your gluing line includes the following:

- MFE-150 Lateral Chain Feeder: The MFE-150 receives the slats and guides each piece through the glue application device.

- Glue Applicator with Measuring System: The Width Measuring Device calculates the width of the slats moving along it to detect the last slat that will not receive glue, therefore creating a dry joint in the panel. Customer could expect saving on glue consumption as by 20% to 30%.

- Panel Forming Zone (ALYX): All slats exiting the glue applicator are guided toward a transfer mechanism that then side-shifts the slats one against the other until the panel has reached its desired width.

- Panel Accumulation Conveyor (ALYX): As soon as the first panel is completed, a holder moves the panel to allow assembly of the second panel. The holders move the panels along the conveyor towards the Clamp Carrier.

- Two-Axis Automatic Loader (ALYX): The loading arms move between the clamps of the carrier to unload the dry panel on the exit conveyor, and then load the new glued panels into the clamps.

Depending on specific needs, it might be useful to add a

MANYX at the start of the line as well as a

GANTRYX at the end.

This equipment will also allow you to achieve a faster, more uniform panel production with a clean, programmable gluing system.

You might also like: