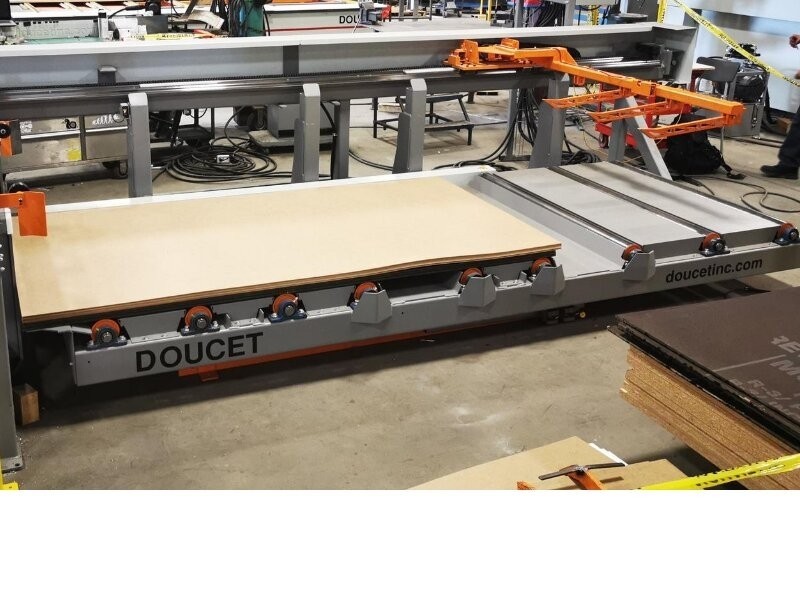

LATERAL CHAIN FEEDER FOR MOULDERS MFE-150 / MFE-300

The MFE-150 Lateral Chain Feeder for Moulders is designed to maintain a feed rate of up to 150 feet per minute of material of fixed or varying lengths in a moulder, while the MFE-300 maintains a feed rate of up to 300 feet per minute.