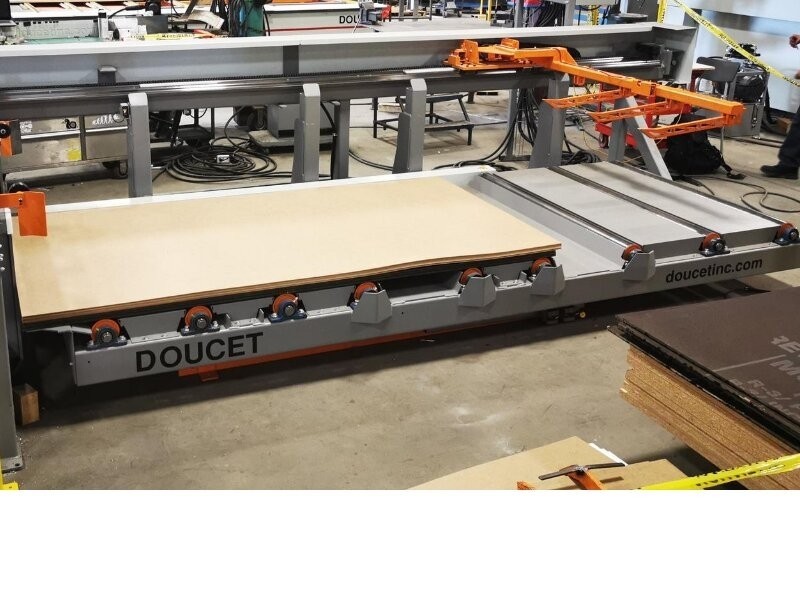

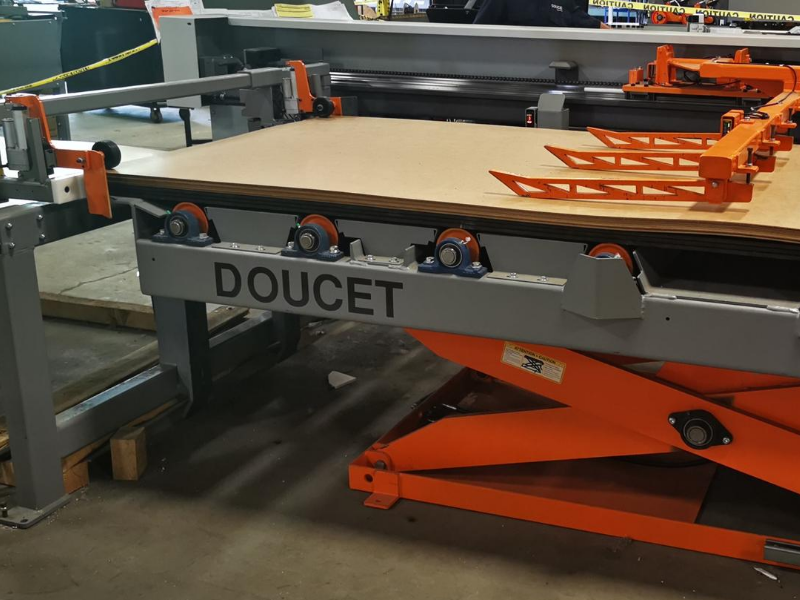

AP Automatic Panel Feeder in action

The AP Automatic Panel Feeder is designed to feed panels up to 4 or 5 feet wide by 8, 10, 12 or 16 feet long onto any receiving unit.