Multi-blade or single-blade saw: which type to choose? Many manufacturers of flooring, mouldings, RV components, cabinet doors or siding who must process engineered panels daily are asking themselves this question.

For high-volume manufacturers, the RS-75 and HRS-120 panel saws are two interesting multi-blade saw models that can ease the task of edging and grooving non-ferrous engineered panels. Designed for speed and efficiency, particularly in the case of the HRS-120 high-speed saw, panel saws can easily be automated with the addition of auxiliary equipment.

Acquiring a panel saw allows you to increase your production rate and ensure the standardization and repeatability of your finished product, grooved or edged. It can therefore be a profitable investment, provided you really need it!

To help you decide, we'd like to start by exploring the features of the Doucet RS-75 and HRS-120 panel saws and learn more about the differences between the two models. The benefits of these saws over similar products on the market will also be discussed. This equipment does come at a price, which you'll certainly want to know before you buy, and who knows, consider implementing other Doucet machines to automate your edging and grooving operations.

I'm Pascal Doucet, Vice-President Sales at Doucet. For over 25 years, I've been helping manufacturers in the secondary wood processing sector, as well as companies in a wide range of industries, to automate their operations. Always on the lookout for new technologies and trends, my team and I are committed to offering businesses the very best in productivity enhancement!

TABLES OF CONTENTS

- Production Description

- Differeces between the model RS-75 and HRS-120

- Who is the Panel Rip Saw model RS-75 and HRS-120 made for?

- Can other equipment do the same work?

- Advantages and disadvantages of the Panel Rip Saw model RS-75 and HRS-120?

- What does the competition offer? How does the competition measure up?

- How does the competition measure up?

- Which are the main questions the customer has durig the buying process?

- Which factors influence the total cost of an Panel Rip Saw?

Production Description

The RS-75 and HRS-120 are two models of continuous-feed panel saws for processing plywood and engineering panels made from a variety of materials such as MDF, HDF, wood, PVC, polystyrene foam, plastic and more.

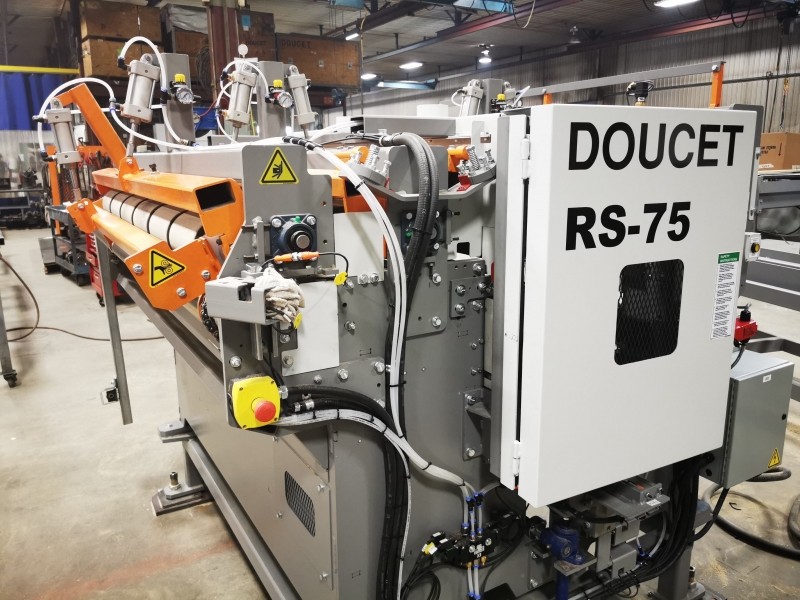

RS-75

The RS-75 model has been designed for edging or grooving wood or plastic fiber panels, while shredding the residues from both sides if required.

HRS-120

Model HRS-120 is a high-speed panel saw used for grooving or edging various glued or finger-jointed wood assemblies, OSB or other composites.

To see all the specifications, features and options of these two panel saws, visit the RS-75 or HRS-120 page.

Differences between the model RS-75 and HRS-120

The RS-75 and HRS-120 panel saw models are distinguished primarily by their cutting power and feed speed. Cutting motor power ranges from 30 to 40 HP for the RS-75 and up to 125 HP for the HRS-120, for an output of 40 to 75 linear feet/minute on the RS-75 and up to 120 linear feet/minute on the HRS-120.

Who is the Panel Rip Saw Model RS-75 and HRS-120 made for?

Doucet panel saws are perfect for businesses needing to quickly process large volumes of panels, up to 61" wide, into specific widths. When processing through the saw, it is also possible to profile or groove as required, by adding additional options.

This equipment is also advantageous for plants producing a limited number of products with standard dimensions. Otherwise, operators would have to constantly change the saw arbor configuration, wasting time and resources and affecting productivity.

Can other equipment do the same work?

For businesses producing a wide range of strip sizes, a Beam Saw may be a more versatile choice. This type of equipment is less easily automated than the RS-75 and HRS-120 panel saws, which are 7 to 8 times faster than the Beam Saw.

This speed is due, in part, to the ability of the RS-75 and HRS-120 panel saws' blades to cut all the strips in a single pass, and without having to go back and forth. Doucet panel saws also deliver consistency and precision that a single blade saw cannot. Indeed, the quality of the finished product obtained with a Beam Saw, for example, will tend to vary according to the operator's dexterity and his ability to press the panel properly onto the fence at the entrance to the machine. Finally, strip stacking at the exit can be automated on the RS-75 and HRS-120 models by adding auxiliary equipment, something that cannot be done on the Beam Saw.

Advantages and disadvantages of the Panel Rip Saw Model RS-75 and HRS-120?

Quick standardization of finished product

Featuring multiple blades that are always positioned at the same points on the saw arbor, the RS-75 and HRS-120 panel saws are highly suitable for ensuring the consistency of the finished product. The equipment therefore transforms raw material more quickly, but also precisely and with more consistency.

Increased productivity

Operators of the RS-75 or HRS-120 can also easily interchange the saw arbor blades to change the dimensions of the strips to be cut or grooved. Most operators have at least 2 saw shafts, which are already prepared to reduce the downtime required for a production changeover. This equipment is therefore an essential tool for increasing productivity in panel processing and boosting production volumes.

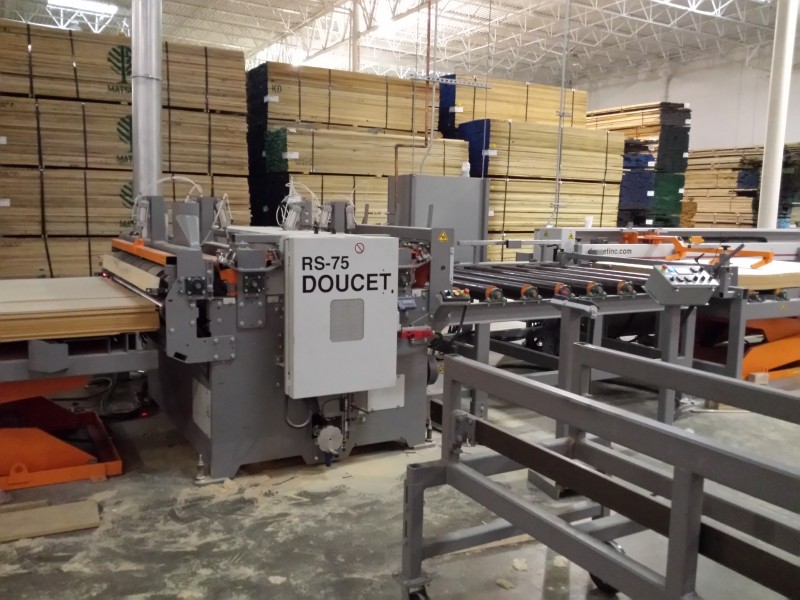

Simple automatisation

By connecting auxiliary equipment to Doucet panel saws, it is possible to feed other equipment in the manufacturing process, such as a moulder, a finishing line or a sander. This transition equipment can, for example, load panels onto the saw and stack or unstack the strips at the exit. Almost complete automatisation of the production cycle reduces the need for human handling, and therefore requires less manpower.

Optimal waste management

The RS-75 and HRS-120 saws shred excess cuttings, making it considerably easier to manage the scrap generated by the processing of engineered panels.

What does the competition offer?

Doucet is not the world's only manufacturer of industrial panel saws. The German designer Paul also offers comparable equipment. They have a very good reputation, but they are more expensive than the Doucet models. Expect longer delivery times for this equipment too.

Taiwanese manufacturers offer panel saws that are far less efficient than Canadian- or German-made models. In fact, saw-shaft loading is much more difficult on Asian equipment.

How does the competition measure up?

Doucet is not the only manufacturer of industrial panel saws in the world. The German designer Paul offers similar equipment. Although they have a very good reputation, they are more expensive than Doucet models. Also, expect longer delivery times for this equipment.

There are also Taiwanese manufacturers offering panel saws that are far less efficient than Canadian- or German-designed machinery. In fact, loading the saw arbor is much more difficult on Asian equipment.

Which are the main questions the customer has during the buying process?

What is the capacity of the RS-75 and HRS-120?

These two panel saws can process engineered panels from 24 to 61 inches wide and a minimum of 4 feet long, without any restrictions in terms of maximum length.

How long does it take to change the saw arbor?

According to the skill and number of operators assigned to the task, the saw arbor can be changed in just 15 to 30 minutes. Two skilled operators should take about 15 minutes to perform this operation.

Which Doucet equipment is suitable for RS-75 and HRS-120 saws?

Several auxiliary Doucet equipments can be combined with one of our panel saws to automatically and continuously feed another piece of equipment:

- AP Automatic Panel Feeder or APV Panel Feeder Stacker;

- MANYX Stacker/Destacker;

- GANTRYX Stacker/Destacker.

Spacers or collars: which option to choose, and why?

Spacers provide better consistency and repeatability than collars. They are therefore an interesting option for productions that don't require frequent changes in blade positioning to produce strips of different widths. Although easy to install and set up, spacers require a storage space large enough to allow them to be sorted by width.

Collars, on the other hand, are more versatile and require greater precision and skill to install and adjust, as each collar must be positioned independently on each blade.

Which adjustments need to be made when panel thicknesses are changed?

The Doucet panel saws are equipped with upper pressure rollers that provide panel traction during passage. The press rolls are driven by pneumatic cylinders, which lift between panels, so no adjustment is required for a ¼-inch thickness change or less. For a greater variation in thickness, a rotary stop must be turned, which decreases or increases the stroke of the press rolls as required. The rotary stop can be preset to suit the panel thicknesses frequently used in production. If profiling or grooving is required, it may also be necessary to adjust the height of the saw arbor.

The reference for grooving is the underside, so if the grooving is the same regardless of panel thickness, no adjustment is required. However, if the grooving depth changes with panel thickness, the height of the saw arbor must be adjusted. The saw arbor is equipped with a crank system (or optional electric system) to reach the desired height.

Which factors influence the total cost of an Panel Rip Saw?

- What’s the basic price of panel saws? Excluding the cost of auxiliary equipment needed to fully automate your grooved or cut panel production line, you'll pay between $150,000 and $175,000 for the RS-75 model, and between $200,000 and $250,000 for the HRS-120 model.

- What determines the total price? The price you pay will vary depending on the level of automation you need to get the most out of your panel edging or slotting operations. Buying several saw shafts will also increase the total cost of acquiring such equipment.

- Which subfactor affects costs? Spacers may be more expensive than collars, according to the number of spacers required, although this price difference remains minor in comparison to the total cost of the equipment. The number of blades will also slightly fluctuate the bill. However, using more blades will mean fewer sharpenings.

- Installation time? Installation of an RS-75 or HRS-120 saw takes about 2 days, including training for operators (which is included in the cost of the equipment). However, the installation of auxiliary equipment requires more time.

- Maintenance costs? Regular maintenance of this equipment includes, among other things, sharpening the saw blades.

- Warranty? 1 year, including parts and labor.

For those manufacturers with a large volume of non-ferrous fiberboard or composite panels to process, the RS-75 or HRS-120 multi-blade saw will be an ally, both for optimizing production and for standardizing the quality and dimensions of finished products. Unlike a single-blade saw, the RS-75 and HRS-120 can groove or rip panels into strips of predefined dimensions, in no time at all!

Compatibility of both the RS-75 and HRS-120 with other transition equipment means increased productivity through equipment automation. What's the result? A continuous feed production line that requires very few handling operations, as panel loading and unloading, and strip stacking during edging operations, can be carried out automatically.

Doucet panel saws are well suited to the panel slotting and edging needs of manufacturers in a wide range of industries, thanks to their easily interchangeable saw shafts and the versatility of their spacer and collar configurations.

For more information on the RS-75 and HRS-120, contact us :

- Complete our Inquiry Form online

- Via Email : info@doucetinc.com

- Or call us at : 1 866-673-8876