Are you planning to buy a return conveyor for an edgebander, and looking to budget for your purchase? This article is for you! If you were only buying an edgebander this is a very interesting article to read.

First, you should know that the price of a BT3 edgebander return conveyor varies according to the options you choose. Given that the size of the panels processed establishes the basic cost, you must consider the options that will optimize your edgebander; these will impact the cost accordingly. Based on the goals you've set; you'll be able to analyze the return on investment.

Following the reading of this article, you'll be able to draw up a budget and plan the start-up of a new return conveyor.

So sharpen up that pencil and let's get started!

Basic return conveyor rates

There are 2 main price ranges depending on the width of the rollers:

- 36'' and less

- 48'' and more

In general, for a standard design like the BT3-36, for an edgebander of 20 to 25 feet/minute and adding interesting options like the turner and the panel diverter (PT-90), we are talking about an average price between $30,000 and $35,000, without installation.

If you opt for a BT3-48 or 60, with the same options, prices will vary between $40,000 and $45,000, without installation.

Projects over $40,000 are usually BT3 Return Conveyors that meet special and non-standard needs.

We can help you clearly determine the best BT3 model for your production.

Additional features and options

Obviously, it's all a question of options! The more equipment options you add, the higher the price. That said, the more options you add, the greater your efficiency, and therefore your production capacity! The return on investment can pay off in the short term.

The following are possible options for optimizing your equipment:

- A PT-90 Panel Turner to return long rectangular panels lengthwise after finishing of their narrow sides. Available on all models, this device simplifies processing short sides on long and narrow panels. The panels are turned 90° as part of the transfer process between the receiving and return rollers, thus eliminating panel overhang.

- Panel Deviator: to redeploy narrow parts over several rollers

- Heavy Duty Models for application where panels exceed 200 pounds

- Air Table: aids the user to manhandle the panels effortlessly on a cushion of air

- Steel Rollers covered by with PVC Sleeves

- Additional receiving table length: 2’, 4’ or 7’ up to a total length of 7’, 9’, 12’

- Additional return length, proportional to the equipment available per increments of 1 foot

- Additional transfer width available per increments of 1 foot

- Set of 3 additional transfer belts, for heavier panel application

- Quick release disconnects on caster mounting for return section

- Panel Accumulation Mode on return rollers

- Angular Return Section

- Open frame panel with additional photo eye

- Moveable support ledge for high volume of short parts

To learn more about how to use this equipment and all its benefits, we recommend that you consult Complete Guide – BT3 Return Conveyor for Edgebander. You may also watch a BT3 in action on our You Tube channel.

Which factors impact the total price?

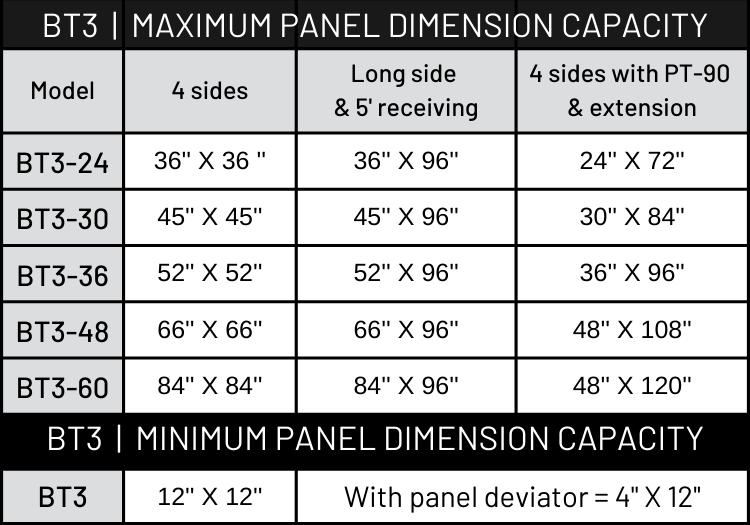

The first factor that impacts the price is the size of the processed panels. It will define the width of the rollers and therefore the BT3 Return Conveyor. As an example, this table will help you choose the right model, choose the one that corresponds to 85% of your production.

Then, a standard model vs. a heavy-duty model or one adapted to your needs will also have an impact on the price of the equipment.

The length of the edgebander plays an important role. Indeed, the BT3 Return Conveyor must be adapted to its length.

Finally, it's a question of options! Obviously, the more options you add to the machine, the more expensive it becomes. That said, the more options you add, the more your productivity should be improved!

Shipping charges

Shipping charges may vary according to delivery location. We ship throughout Canada and the United States.

Installation costs

For a product like the BT3-36, most customers install it by themselves or with the help of their local distributor. Just follow the installation guide or this tutorial! For this product, the main module is already assembled, only need to fix the return conveyor’s extension to the main unit. Usually, most companies already have a good mechanic in the factory who can easily handle the installation. Allow a full day for installation.

For some BT3 Return Conveyors like the BT3-48 and 60, I strongly suggest that they be installed by our technical experts, especially since they are disassembled for shipping. Here, allow two days to complete the installation.

Because of their proximity, distributors usually take care of the installation. Since the

BT3 Return Conveyor is typically sold as a combo with an edgebander, they will install both machines at the same time.

Conclusion

Still hesitating to make the purchase? Allow me to share with you some additional facts for further consideration.

It has been shown that processing 85% of the panels with only 1 operator and a BT3 Return Conveyor is more profitable compared to 100% of the panels with 2 workers (no return conveyor). Incredible, isn't it? It's because of the human factor! Considering the manpower cost per hour, the attendance, the risk of injuries, etc. Imagine your gain with 100% of your production and a return conveyor like the BT3!

My years of experience in assisting companies like yours, specifically around BT3 Return Conveyors, has shown me how fast the return on investment is with the addition of such equipment. Less than 8 months! And that's not including the savings in direct labor, as well as the improvements in health and safety in the plant.

For more information

Doucet is a North American leader in the design, manufacturing, and integration of advanced solutions for woodworking companies.

For more details on the BT3 Edgebander Return Conveyor, please consult the product web page or brochure, as well as the Complete Purchasing Guide.

All our products are designed and manufactured to fit your environment. Contact us for more information!

You have three options;

- Fill out our quote request form,

- Contact us by email at info@doucetinc.com

- Call us at 1-866-673-8876