TABLE OF CONTENTS

For whom is (and is not) a return conveyor for edgebanders made?

Advantages of a return conveyor for edgebanders

Technical characteristics of the BT3 return conveyor

Compatibility with your edgebander

The best model to suit your needs

Return conveyor capabilities

Installation

Is there any risk of damaging your panels?

Open frame management

Best options to add

Difference between the edgebander return conveyor and the intelligent return conveyor system

The costs

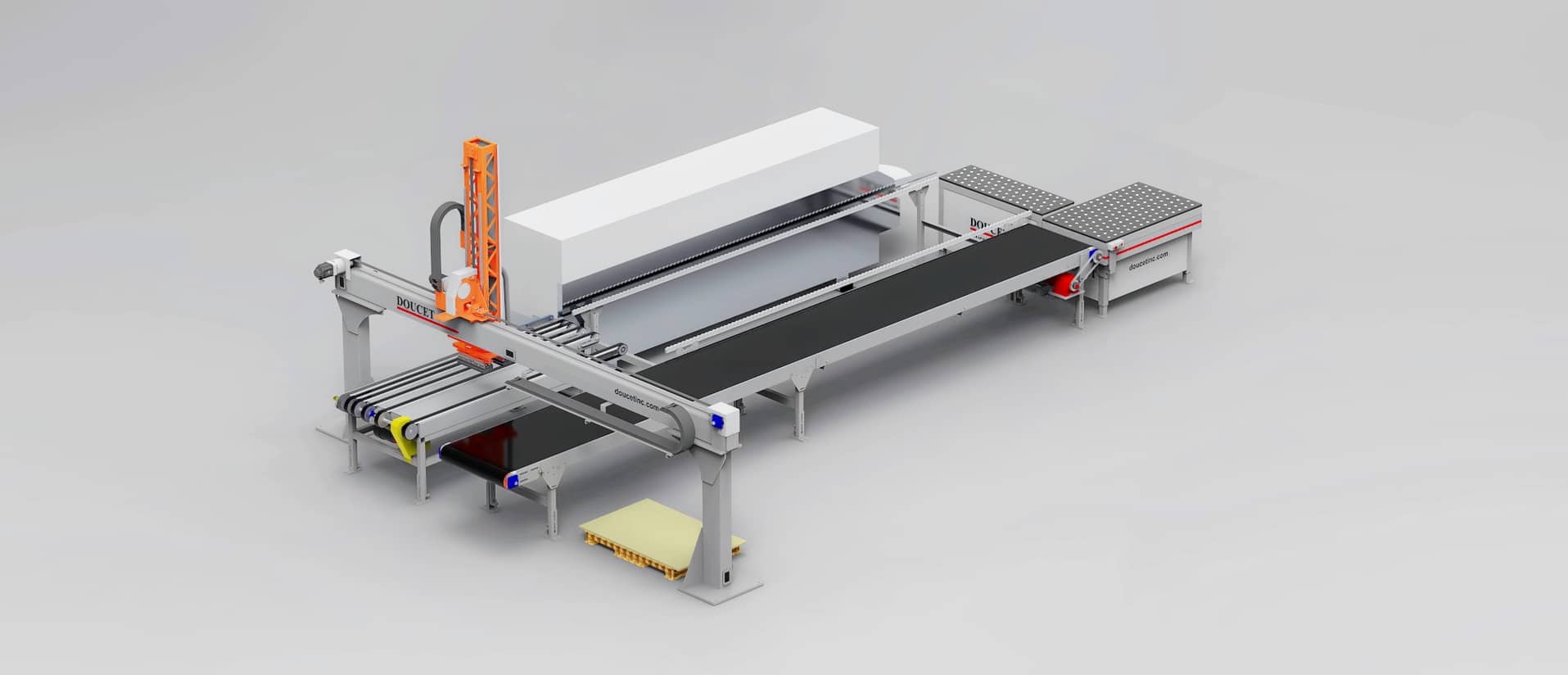

Are you planning to buy an edgebander? Are you looking to optimize your current one? If so, at this very moment, you are analyzing the different options; how many operators will I need? Do I add a BT3 Return Conveyor? What will be my maximum speed? What will be the possible part sizes? You're overwhelmed with questions right now, aren't you?

I perfectly understand your state of mind! I have been working with woodworking manufacturers for over 25 years. Indeed, the wood transformation sector has no secret for me! I was involved in the design of 3 generations of the BT3 Return Conveyor, and at a certain point, I was a service engineer installing them at our customer’s manufacturing locations. Today, more than 5 BT3 Return Conveyors a week are delivered to our customers across North America!

In this complete guide of the BT3 Return Conveyor, you will find the answers to your questions and the information you need to make your decision. You will find the technical specifications and available options. I will explain for whom the BT3 Return Conveyor is (and isn't) made, what are its advantages, the return on investment (ROI) and finally I will discuss the costs associated with the purchase of such equipment.

Are you ready to become the next BT3 Return Conveyor expert?

To whom is the BT3 Return Conveyor made for (or not made for)?

Basically, the BT3 Return Conveyor is designed to be combined/paired with an edgebander to increase the machine's efficiency by reducing the need for manpower. I will go into more detail on this point and later in the advantages.

It is mainly aimed to cabinet manufacturers (doors and cabinets), furniture manufacturers and commercial furniture manufacturers for the hospitality and healthcare industries, just to name a few. To have a quick return on investment, the company must produce a certain volume, which is usually found in factories with 20 employees or more.

If you consider your production volume to be low or if you use your edgebander less than 2 hours per day, you may not need equipment like the BT3 Return Conveyor. For example, a small woodworking shop operating the edgebander 1 to 2 hours per day, other model like the XPRS Return Conveyor will better suit their needs.

What are the advantages of a return conveyor like the BT3?

A direct gain in manpower

To operate an edgebander without a BT3 Return Conveyor, 2 operators are needed. One at the entrance who places the part in the edgebander, and one at the exit who picks up the part and stacks it on the floor on a pallet or turns it over to continue the sequence.

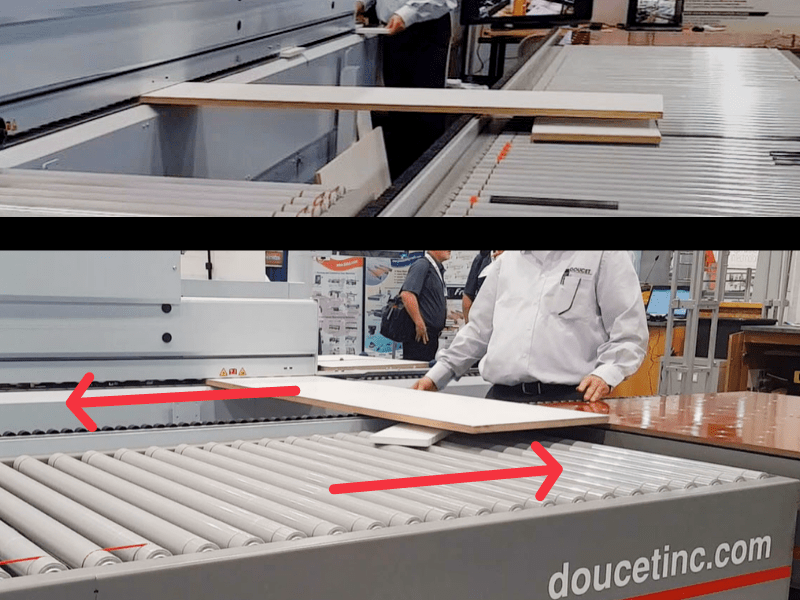

As an example, a cabinet door panel requiring edging on all sides consists of 4 phases in the sequence. Therefore, the part must pass through the machine 4 times. The return conveyor, like the BT3, allows the parts to be returned without the need for a second operator at the edgebander out feed.

The first benefit of the BT3 Return Conveyor is to remove the person at the exit. Why remove the person at the end rather than the person at the beginning? The reason is that the entrance to the edgebander is critical to the positioning of the component to guarantee the accuracy of the edgebanding. At the exit, if the part is well received, does not get damaged, and returns to the operator at the entrance for the rest of the sequence, the job is done!

Also, in times of labor shortages, it is critical to utilize workers in value-added positions for the company. The output operator performs repetitive tasks, and his role is not very rewarding, which is why it is difficult to find people to fill this position.

A very quick return on investment (ROI)

Most manufacturers working full time with their BT3 Return Conveyor, model BT3-36 for example, have a return on investment in less than 8 months.

As an example, we estimate the average cost of an operator with salary and social benefits at $50,000.

The average cost of the BT3 Return Conveyor is about $30,000 (you will find more details in the section how much does a BT3 Return Conveyor cost?).

Because a BT3 Return Conveyor allows the removal of the operator at the exit, it is estimated that the company recovers its investment after the 8 months, and this, without considering the reduced risk of injury which represents significant sums for the companies.

Health and safety at work

The health and safety of workers is a priority for all companies these days. The BT3 Return Conveyor allows the safe return of panels of different sizes and weights. Sometimes the operator is faced with a 65, 100 or even 150-pound door or countertop. Unfortunately, one person cannot handle these pieces without risk of injury. Two workers are needed at the entrance and two at the exit. However, the BT3 Return Conveyor does not require an operator at the exit, so there is no risk of injury. In addition, by adding an air table at the entrance, the handling of the parts is easy and safe and can be done by a single operator.

Description of the BT3 Return Conveyor

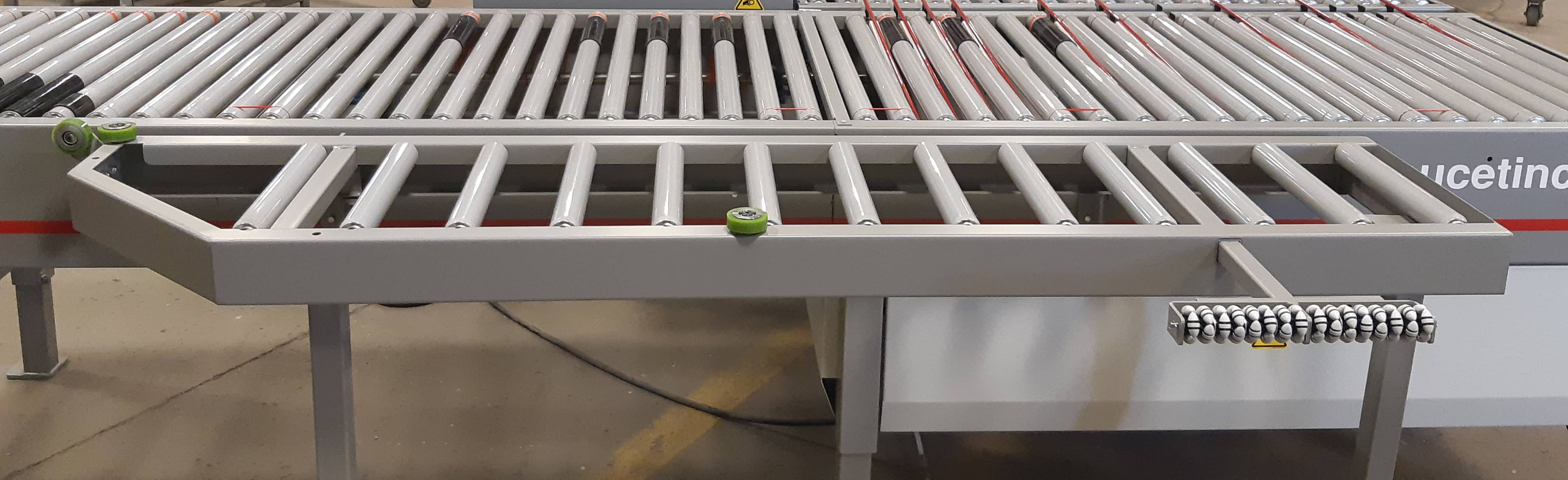

The BT3 Return Conveyor is designed on a modular frame, it has a transfer system that is quick, simple, and very efficient. It is available in 5 widths: BT3-24, BT3-30, BT3-36, BT3-48, and BT3-60.

Please visit the Return Conveyor for Edgebander BT3 to find all the features and options in a more formal way.

In this article, I specifically answer your questions!

Is the BT3 Return Conveyor compatible with your edgebander?

Of course! The BT3 Return Conveyor is compatible with all edgebanders brands. A monitoring is done every year to allow the adaptation of the BT3 Return Conveyors, mainly at the out-feed level. A simple picture of the edgebander out feed, and we can confirm quickly which interface is needed to match your edgebander.

What is the best model for your needs?

Return conveyors are manufactured up to 60 inches wide. In most cases, I suggest to my customers the BT3-36 (36") model. This is the most popular size because it offers the best capacity/price ratio. For example, it's possible to make a panel up to 3 feet by 8 feet (4 sides) without any problem. In my opinion, for the price, it's the best purchase! The BT3-24 and BT3-30 are less common although if you are limited by your floor space, these are good options for you! Although they are smaller, there isn’t a big impact on the price, meaning it's not much less expensive than a BT3-36.

If you are dealing with large parts on a regular basis, you will have to consider a model like the BT3-48 or BT3-60. They are more expensive because of the width of rollers, but you will have a guaranteed gain in productivity.

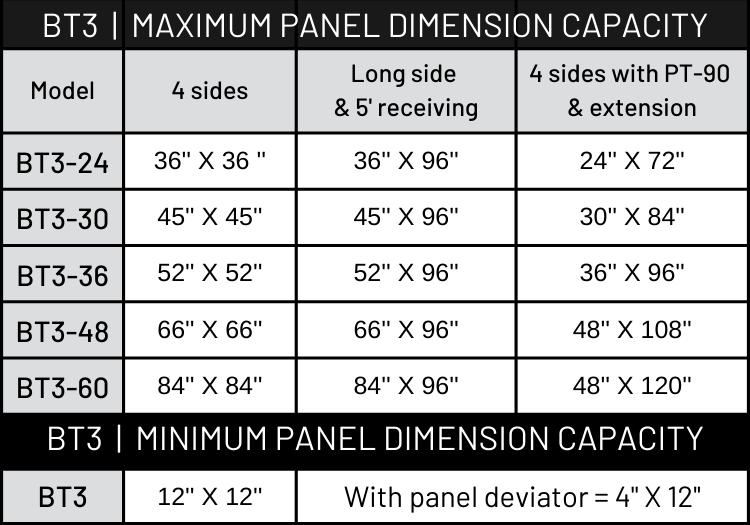

See the dimensions capacity chart :

What are the capacities of the BT3 Return Convoyer?

What is the smallest part size processed by the BT3 Return Conveyor?

If you are handling small parts under 6", you should consider adding a panel deviator. It allows the part to be rotated 45 degrees so that it remains stable on the return conveyor.

If you are dealing with large bundles of small parts, then I suggest you opt for the option D115-319, a moveable support ledge for a high volume of short parts. It allows to keep a maximum production rate despite the small size of the panels.

What is the largest part size that can be treated by the BT3 Return Conveyor?

If you are processing large panels that are very heavy, in addition to choosing a larger model like the BT3-48 or 60, I also suggest choosing a "Heavy Duty" type. They are designed with stronger materials like steel rollers, the pneumatic cylinders have a bigger diameter, and the belts are also adapted.

The standard BT3 Return Conveyor is recommended for panels weighing less than 200 lbs, while the BT3 "Heavy Duty" will be suggested for pieces weighing more than 200lbs. (Up to 350 lbs)

What if you’re managing large parts occasionally?

It's easy! You will need to use the bypass which allows you to cancel the transfer sequence and give the relay to the operator. There's no need to invest 40% more in a larger machine because you occasionally process large panels.

For example, if you are processing non-standard parts 3 to 4 times a day, I suggest going with a 36" and using your operators at the exit for those few exceptions.

The bypass is now included with all BT3's, it is a great asset!

Is it possible to customize the BT3 Return conveyor to your specific needs?

Although the existing models and options meet most of the market's needs, it's possible to adapt the BT3 Return Conveyor to your reality!

How fast does the BT3 Return Conveyor handle the edgebander?

The BT3-36, for example, has been installed and tested on several 30 meter/minute edgebanders, which are currently the fastest machines on the market. The BT3 Return Conveyor can be adapted to all edgebander speeds!

What about installation? Can you do it yourself?

Well, that depends on the size of the BT3 Return Conveyor you choose!

For a product like the BT3-36, most customers install it by themselves or with the help of their local distributor. Just follow the installation guide! For this product, the main module is already assembled, only need to fix the return conveyor’s extension to the main unit. Usually, most companies already have a good mechanic in the factory who can easily handle the installation. For some BT3 Return Conveyors like the BT3-48 and 60, I strongly suggest that they be installed by our technical experts, especially since they are disassembled for shipping. In addition, for these large machines, the ratio of installation costs is well worth it, compared to a smaller machine. For example, if you invest $100,000 for a BT3 Return Conveyor, adding a $4,500 installation fee is quite reasonable. On the other hand, that same $4,500 for a $30,000 BT3 Return Conveyor is harder to justify!

Because of their proximity, distributors usually take care of the installation. Since the BT3 Return Conveyor is typically sold as a combo with an edgebander, they will install both machines at the same time.

To learn more about the BT3 installation, I suggest to watch this video!👇

Is the return conveyor going to damage your panels?

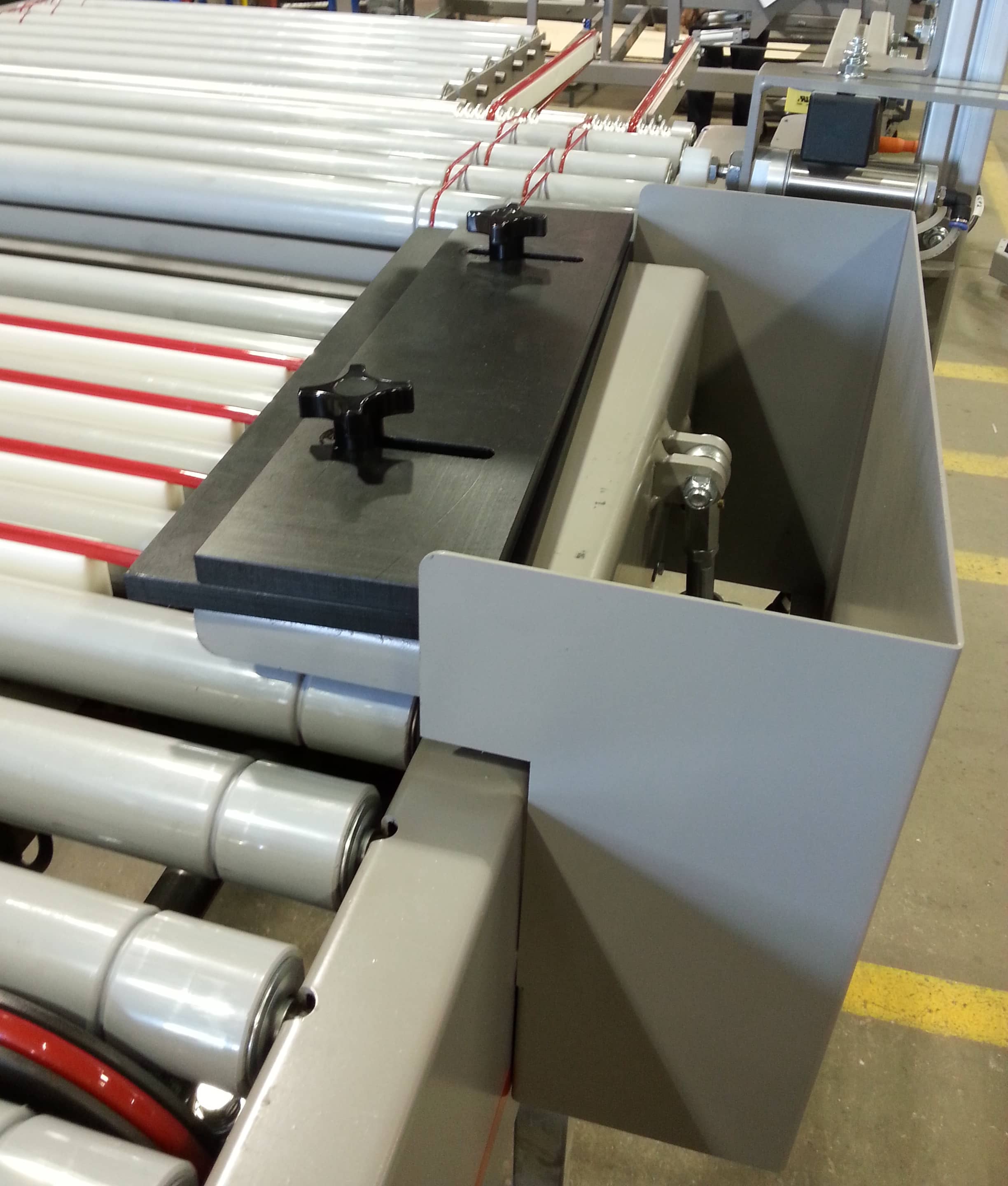

Of course not! The BT3 Return Conveyor stands out for this reason! It is designed with PVC or PVC-coated steel rollers, specifically to ensure that surfaces such as melamine are not damaged.

One of its great strengths is what we call active transportation. This design allows your products to be handled carefully and smoothly. Our belt transfer system processes the finish surface and edges of your products with the highest care. As the receiving rollers retract, they deposit the panels on the transfer belts. The transfer belts, set in UH MW supports, extend to move the panels to the BT3 Return Conveyor.

Does the BT3 Return Conveyor handle open frames?

Absolutely! However, if your volume is low, I suggest using the bypass. If your volume justifies it, there is an option to detect panels differently.

What are the options you should consider? (The more common).

The panel turner (PT-90): turns long rectangular panels (90 degrees) to allow for 4-sided edging operations. The addition of the PT-90 will increase the capacity of your return conveyor in terms of part size.

The air table: It's designed to make the handling of panels easier by lifting them on an air cushion. The air table is located at the operator position. By simplifying the handling of heavier panels, it adds a lot of ergonomics and safety to the operator on the job.

Speed integration with the edgebander: By default, the return conveyor speed is adjusted with the help of a pedometer. If needed, an option is available to synchronize the speed of the return conveyor to follow the edgebander speed.

What is the difference between a return conveyor and an intelligent panel Return Conveyor system?

Compared to the BT3 Return Conveyor, the RETYX is intelligent! Thanks to a simple programming, it knows which orientation to return the panel or when the panel is at its last pass and performs the requested task, such as stacking it on a pallet rather than returning it to the operator at the entrance of the edgebander, who only must feed the machine with a new part. The handling is therefore reduced considerably during a production day. With the RETYX, you can produce an average of 400 to 500 more passes per day.

How much does a BT3 Return Conveyor cost?

There are 2 main price ranges depending on the width of the rollers:

- 36'' and less

- 48'' and more

In general, for a standard design like the BT3-36, for an edgebander of 20 to 25 feet/minute and adding interesting options like the turner and the panel diverter (PT-90), we are talking about an average price between $35,000 and $40,000, without installation.

If you opt for a BT3-48 or 60, with the same options, prices will vary between $45,000 and $50,000, still without installation.

Projects over $45,000 are usually BT3 Return Conveyors that meet special and non-standard needs.

Which factors impact the total price?

The first factor that impacts the price is the size of the processed panels. It will define the width of the rollers and therefore the BT3 Return Conveyor. As an example, this table will help you choose the right model, choose the one that corresponds to 85% of your production

Then, a standard model vs. a heavy-duty model or one adapted to your needs will also have an impact on the price of the equipment.

The length of the edgebander plays an important role. Indeed, the BT3 Return Conveyor must be adapted to its length.

Finally, it's a question of options! Obviously, the more options you add to the machine, the more expensive it becomes. That said, the more options you add, the more your productivity should be improved!

In conclusion, it has been shown that processing 85% of the panels with only 1 operator and a BT3 Return Conveyor is more profitable compared to 100% of the panels with 2 workers (no return conveyor). Incredible, isn't it? It's because of the human factor! Considering the manpower cost per hour, the attendance, the risk of injuries, etc. Imagine your gain with 100% of your production and a return conveyor like the BT3!

My years of experience in assisting companies like yours, specifically around BT3 Return Conveyors, has shown me how fast the return on investment is with the addition of such equipment. Less than 8 months! And that's not including the savings in direct labor, as well as the improvements in health and safety in the plant.

Now that you know all the secrets of the BT3 Return Conveyor, if you've read this far, it's obviously a great piece of equipment to add to your production cell!

Doucet is a North American leader in the design, manufacturing, and integration of advanced solutions for woodworking companies. All our products are designed and manufactured to fit your environment. Contact us for more information! You have three options; fill out our quote request form, contact us by email at info@doucetinc.com or call us at 1-866-673-8876.