SYSTEM'S MAIN FUNCTIONS

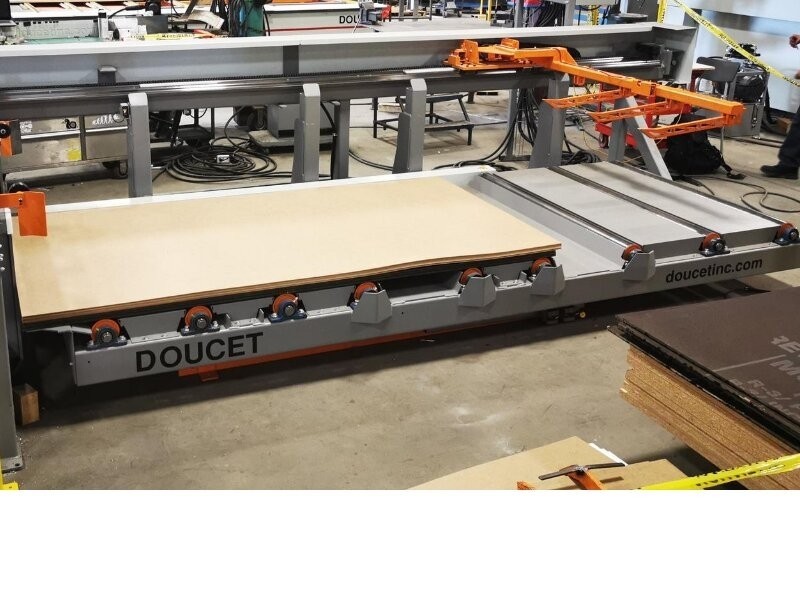

- A wood sheet is placed on the AP automatic panel feeder, which separates the panels at the entry point and feeds them towards the first chain transfer;

- The ERS-96 receives the panels. This Grooving Saw is mainly designed to make the curved groove under the core layer;

- The panel comes out of the ERS-96 and is transferred by the second roller conveyor with chain transfer to the next step;

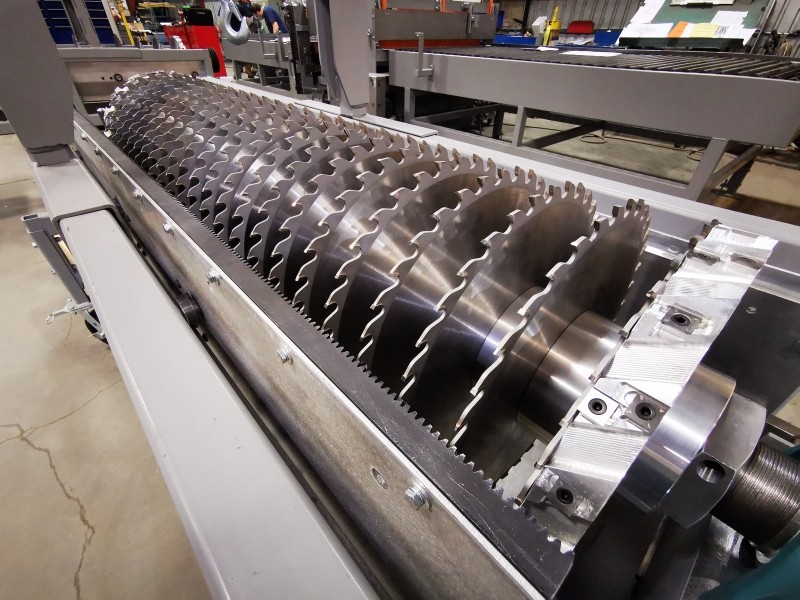

- The panel is received by the RS-75, which cuts it into multiple strips with predetermined widths. This multiple blade rip saw can run at a feed rate of 75ft per minute and comes with a 40 HP motor for the arbor;

- The strips are coming out from the saw and landing over a 5 x 8 exit scissor lift moving down between each layer of strips.

The RS-75 has a second motor for the feed rollers, which consist in four feed rollers in the bottom and four pressure rollers on the top. It has a 60'' width capacity for the panel.

The operator will need 15 to 20 minutes to swap the arbor from the order.

The AP Automatic Panel Feeder has a hydraulic power unit for moving the lift table, 3-finger pusher arm and motorization of rollers. Three (3) rollers are powered to bring bundle to reference line. All operations can be performed in manual, semi-automatic or automatic mode as desired.

This specific

production line includes the following equipment: