Are you an owner, manager, production manager or a project manager in a company operating in the field of metal sheets and having needs for sandblasting or sanding of large surfaces?

You run a metalworking manufacturing business and want to carry out large-scale projects? Does your polishing equipment have insufficient capacity to handle large, heavy metal plates?

The exclusive APP Automatic Stroke Polisher for Metal Plate could help you to optimize production by automating the sanding and sandblasting of metal plate of unusual size and weight.

The implantation of such equipment is an investment that you will not take lightly. This article is intended to help you decide whether the APP model is right for your company's needs. You will discover the main features of the APP Automatic Stroke Polisher and the advantages of automating your metal sanding processes to ensure the profitability of your operations as well as the safety of your work teams.

With over 30 years of experience in the industrial field, I fully understand the challenges that you face on a day-to-day base. Like you, I have had to try out several pieces of sanding equipment before finding the ideal model to produce a quality finished product. I am also aware of the issues surrounding the recruitment of qualified workers and, during my career, I have often had to advise clients in their efforts to optimize their production.

It is therefore with great transparency that I answer the main questions asked by business leaders like you about the APP, particularly regarding the acquisition and installation costs to be expected.

Table of contents

- For whom is the APP made for?

- Product description

- What are the problems, issues and situations that lead the customer to purchase the APP model?

- What are the customer's main questions in their buying process?

- Advantages and disadvantages of the APP

- Comparison with other Doucet Sanders Products

- How expensive is an APP?

For whom is APP made for?

Strong and efficient, the equipment has been specifically designed to support high loads to assure the consistent and secure sanding of very large metal plates. For instance, the APP could be used by the marine industry to restore a large metal piece with rust damage, to smooth out defects on a rough surface or to remove the protective film on a steel surface.

The APP is not the preferred option for polishing small metal parts, while the PMCTA and PMCT are much better choices.

Product Description

The APP is designed to automate the sanding and polishing of large stainless steel or aluminum plates up to 12 feet long by 12 feet wide. The APP's fixed table is strong enough to support a load of up to 8,000 pounds. Once the plate is loaded on the table, a motorized axis allows the vertical adjustment of the sander according to the thickness of the material to be processed. The automatic polishing cycle can then be set from the digital interface of the on-board computer. The sander is powered by an electric motor and moves along the longitudinal and transverse rails at a speed adjustable to the length of the plate.

Discover all the technical features in addition to the options of the Automatic Stroke Polisher for Metal Plate.

What are the problems, issues and situations that lead the customer to purchase the APP model?

Overcome employee shortages

Programmable and independent, the APP requires minimal human intervention, which allows businesses to assign their workers to other tasks while the sander does the work; an asset in these times of labor shortage. Also, the operation of this equipment does not require any particular expertise on the part of the worker.

Easy and safe for workers to use

Once the plate is set on the sander's fixed table, no other handling is required until the operation is completed, at which time the metal plate must be removed from the equipment. By reducing handling, the APP contributes to improve the workers comfort and safety. Otherwise, workers would need to work in highly non-ergonomic positions to polish metal plates of such dimensions. In addition to reducing the risk of work-related injuries, this equipment also helps prevent avoidable accidents related to the handling of heavy and large materials.

Consistency and quality of the final product

The automation of the polishing and sanding process makes it possible to obtain a uniform and regular finish with little effort. The APP greatly reduces the time and cost of obtaining such a high-quality finished product.

What are the customer's main questions in their buying process?

Which sizes of metal plates can the fixed table of the APP accommodate?

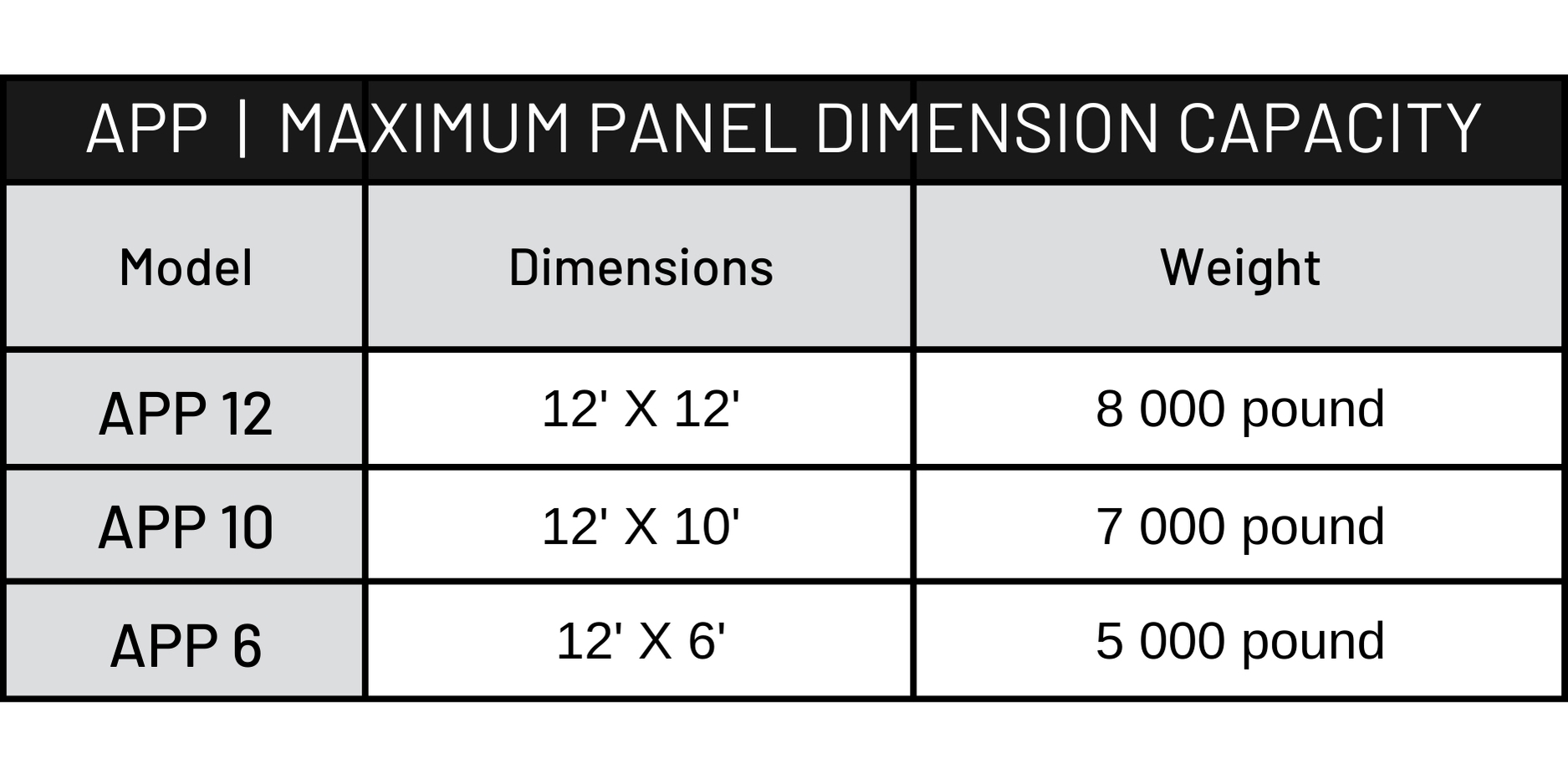

There are three different models of APP that can be adapted to the different needs of the manufacturers according to the size and weight of the plates to be polished:

The dimensions of the APP can also be customized to meet the more specialized needs of certain manufacturing industries.

The dimensions of the APP can also be customized to meet the more specialized needs of certain manufacturing industries.

Which speed does the APP reach and how much performance can be expected?

The APP, like the LPP and PMCTA, are equipped with programmable travel speeds. This allows you to program various speeds depending on the size of the plates. The polishing time, and therefore the efficiency of the equipment, will depend on the average size of the plates to be processed.

Is the APP compatible with any other equipment?

The APP is a single-use piece of equipment that stands on its own. However, a forklift is required for handling the metal plates on the fixed table of the sander. As well, the acquisition and installation of a dust collector or the connection to an existing dust collector will be necessary to ensure the respiratory safety of the workers.

How wide is the floor space required for the installation of the PPA?

For the standard model, a minimum of 18 feet of space is required - the 12-foot-long sander plus the two side rails and the floor rails - and 12 feet deep. For the other APP sander models (APP 6, APP 10, APP 12), the required space depth will be less. In determining which APP model to select, you should consider your needs as well as the actual space you have available.

Learn more about the dimensions of the Automatic Stroke Polisher for Metal Plates, model APP by consulting the data sheet of this equipment.

Advantages and disadvantages of the APP

Advantages

The APP is the only equipment available in North America that can polish such large, heavy and thick metal plates. To locate a machine comparable to the APP, businesses must look to Germany. This overseas importation is expensive, in addition to longer shipping times and occasionally challenging customer service.

Disadvantages

The APP has a single sanding belt. The addition of a second belt is not an option on this unit. As a result, the sanding paper has limited life, so the belt may need to be changed more regularly. But since the APP's belt is longer than other sander models, at 420 inches in length, the belt lifetime remains very good.

Comparison with other Doucet Sanders Products

Other models of sanders may be suitable for polishing and sanding metal plates as large as those that the APP can accommodate. However, the other available options do not match the strength of the APP, since they do not have the same load capacity. For example, the PMCT and PMCTA models can handle plates up to 12 feet long by 4 feet wide, with a maximum load of 1,000 pounds for the PMCT and 500 pounds for the PMCTA.

How much is an APP?

- Which factors impact the total price: The cost of a plate sander carriage varies between $117,000 and $135,000 depending on the configuration chosen, i.e. the load and plate size requirements of your operation.

- Which sub-factors impact the costs: The cost of the delivery and installation of the APP are not included in the cost of the unit. According to the model chosen, it should take about 3 days to install the equipment.

- Are there other costs involved? To use this equipment, it must be connected to a dust collector. If you don't have an efficient dust collector, you will need to purchase and install one. These acquisition costs, as well as those inherent to the connection of the APP to your existing central dust collector, are additional to the final bill.

- Training: A half-day training session is included in the installation of the APP to allow your employees to become familiar with the machine's digital computer interface.

- Maintenance costs : Maintenance costs associated with the APP are minimal, especially if good preventive maintenance practices are incorporated into the machine operators daily routine. Besides frequently lubricating the sander's components, a clean-up of the machine at the end of each shift will help to remove the emery and any abrasive dust particles left over from sanding.

- Replacement parts costs : A contact wheel or pressure pad is provided with the APP polishing carriage. While not subject to premature wear, these components may need to be replaced at a varying frequency depending on the amount of time the machine has been in use. The graphite surface of the pressure pad will be worn and will need to be replaced. These parts are standard and easily replaceable.

- Additional options : There are two additional options for this equipment, according to your specific needs. For the polishing of heavy but smaller metal plates, it is possible to add a plywood in Russian cherry wood to be able to deposit safely these small parts on the spaced plates of the fixed table. As the boxes covering the belts on each side of the sander open, it is also possible to add safety switches that automatically stop the machine when the boxes are open.

- Warranty: 1 year, parts and labor.

CONCLUSION

In optimizing your production line for polishing and grinding your heavy and large metal materials, the APP will be a valuable ally.

By reducing to a minimum, the handling of heavy and bulky sheets that affect your productivity and the ergonomics and safety of your workers, the APP will greatly facilitate your production process. Due to its leading-edge, autonomous, and automated technology, the APP makes it possible to achieve an unparalleled and consistent level of finishing.

As experts in manufacturing this type of equipment for more than 22 years, we know that automating the manufacturing process is the key to optimizing your production line for polishing and grinding your heavy and large metal materials to make your business more profitable and retain your skilled workforce.

The next step is to test our materials and see the results. There is nothing better than seeing how each and every action you take is going to improve and increase your efficiency. Doucet is a North American leader in the design, manufacture and integration of advanced solutions for woodworking and metalworking companies. Contact us today for more information!

For your convenience we have 3 ways to contact us:

- Complete the “Request a quote” form online.

- Via Email: info@doucetinc.com

- Or call us at: 1-866-673-8876