As part of regular kitchen or bathroom design and layout business, do you need to build a small cabinet doors volume? This article is for you! Here all the information you need about the SDM door clamp and its various options, a model designed to simplify and speed up the assembly, squaring and gluing of cabinet doors in small volume operations.

There are two models available: the RDM and SDM. The RDM "Rotary Door master" is designed for multiple sections around a rotating shaft for quick and accurate assembly, clamping, and squaring of your cabinet doors. It produces large volumes of cabinet doors in a short time frame. This model is not covered under this paper. For further information relating to this piece of equipment, please read the complete guide via this link.

We are Pascal Doucet, vice president sales and Anthony Vigneault, inside sales manager of the company. We have been in the business for many years now and work daily to design equipment to help businesses increase their productivity and deal with labor shortages. We developed the first cabinet door presses in 2004 and we are always on the lookout for new technologies and trends to provide the best for you today and going into the future.

No matter if you produce 1 or 200 cabinet doors per day, you will not regret to have read this paper and the one about the SDM. We will give you detailed information on what our equipment can do.

TABLE OF CONTENTS

- Do you have the buyer profile?

- What are the advantages and disadvantages of a rotary door clamp like the SDM?

- Technical description

- What questions are frequently asked during the purchasing process?

- What are the advantages of a Door Master like the SDM?

- What are similar products on the market?

- The difference between an SDM and the competition

- How much does a SDM cost and what are the factors that impact the price?

Do you have the buyer profile?

The SDM is designed for businesses that manufacture cabinet doors made of wood or fiberboard as a primary or a secondary product in small volume.

This kind of press is most useful for cabinet door manufacturers that produce small and medium volumes of doors for sale to other manufacturers, who use them to produce the final cabinets or as part of their larger projects, such as the manufacture of exterior wooden passage doors.

What are the advantages and disadvantages of a rotary door clamp like the SDM?

A desire to improve efficiency

Many businesses who turn to a SDM door presses use clamps that are attached to a flat surface to assemble the doors. This requires a lot more handling, which extends the assembly time. It also takes multiple steps for every size change of the doors to be designed, which isn't very productive.

With the Rotary Door Master adjustments needed to accommodate different door sizes can be made very easily. The clamps are attached to the fame and have ball bearings in order to let it move easily to the required position.

Accuracy problems

Conventional processes provide variable accuracy and result in finished products which may not be exactly straight. The Doucet equipment solves the problem of inconsistency and conformity due to manual handling by providing a high level of precision. The SDM provides accurate settings and uniform pressure on all four corners for a perfect result.

Removes the obligation to use nails

The SDM allows cabinet doors to be assembled without nails. In the past, doors were often stained or varnished, which effectively hid the nail heads. Nowadays, painting is more popular. While paint sticks well to the wood, it cannot cover the nail heads in a durable way. It is therefore now necessary to glue the doors to get an attractive, unmarked product.

It is possible to assemble doors using nails. This way of working is faster because without nails, a waiting time of 5 to 8 minutes is necessary.

Search for solutions for assembling the MDF

More and more doors are being made of paper covered MDF. While these materials are cheap, they are also fragile and not easily joined with clamps or other conventional methods.

The SDM can adjust the pressure to ensure that it is suitable for the different types of products to get a high-quality product and to avoid breakage.

The need to assemble doors with miter components

Conventional clamps or hardware do not or cannot easily assemble cabinet doors with miter (45-degree angles). The SDM can adjust to this situation with great efficiency.

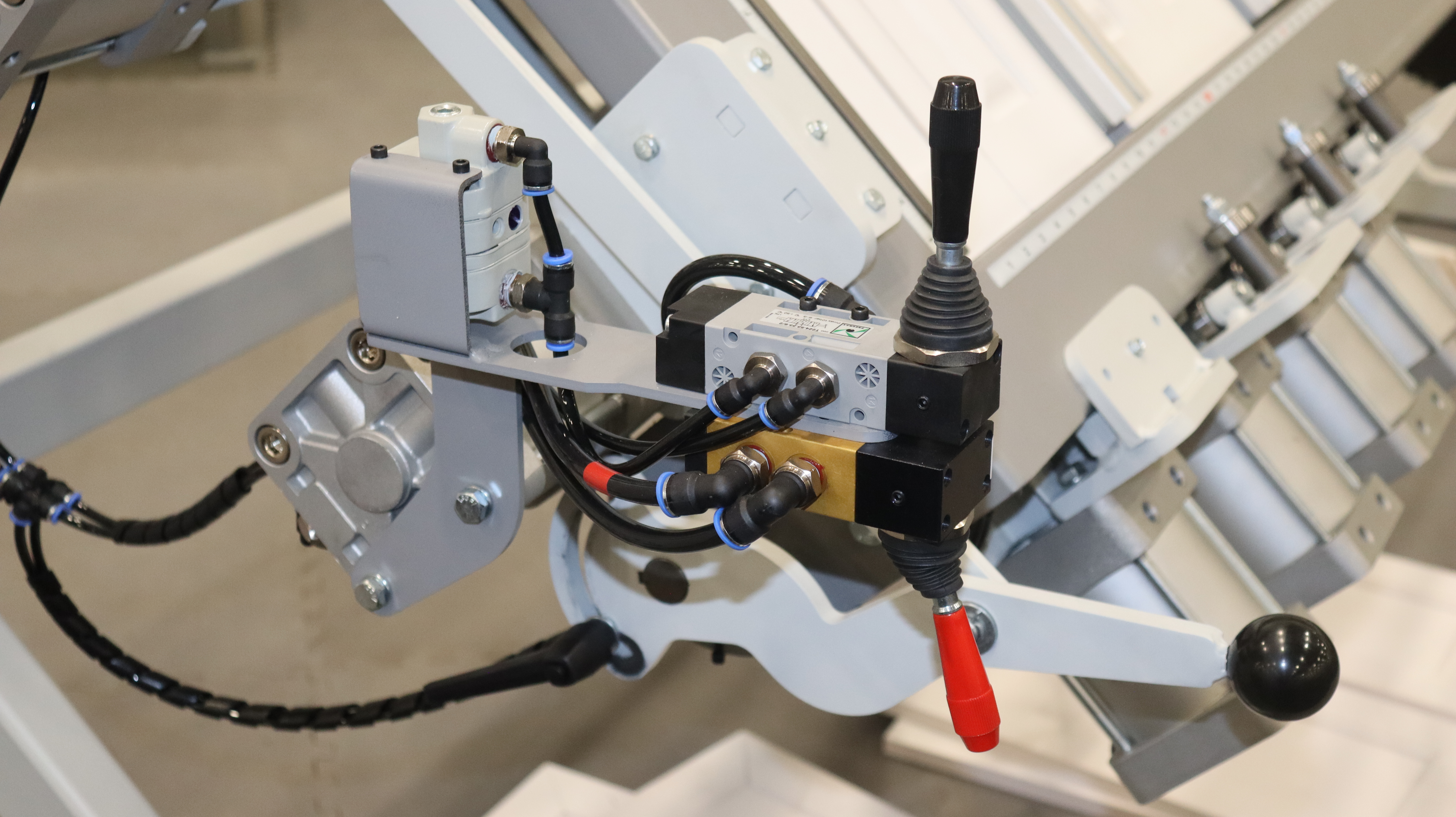

Technical description

The SDM is a Door Clamp for Cope and Stick Doors (90°). The SDM is suitable for the assembly of drawer fronts as well as of a large pantry doors.

Discover all the technical specifications in addition to the different options here :

What questions are frequently asked during the purchasing process?

Will the SDM fit the number of doors I have to manufacture?

Regardless of the number of doors you have to produce, you can find the right equipment at Doucet. Our team of sales reps will direct you towards the best equipment for your type of production.

The SDM is ideal for smaller businesses that produce a smaller volume of doors. The RDM is ideal for businesses producing large volumes of doors for sale.

Which is the minimum and maximum size of doors that can be joined using Doucet's Door Master?

The SDM is offered in a version capable of accommodating doors up to 120" in size. If your requirements exceed this dimension, do not hesitate to contact one of our sales reps for more details on the non-standard models that are available.

If I have to assemble 45° cabinet doors, is the SDM right for me?

The Door Master series of equipment is ideal for use at 45° or 90°, no matter the material being used. It also allows doors to be glued rather than nailed.

For 45° doors, the SDM-Miter or the SDM-TM are options to be considered. Contact us and one of our sales reps will be able to recommend the best equipment for your specific needs.

What are the advantages of a Door Master like the SDM?

The SDM significantly speeds up the production of cabinet doors by reducing handling. It also allows to adjust and to apply a uniform pressure on the different sides of the door joint, which assures a quality and uniform final product, no matter the skills and qualifications of the worker in charge of the task.

Doucet can adapt its "Door Master" series equipment to the needs of its clients. It is possible to adjust the dimensions of the SDM to the precise characteristics of the doors to be produced.

The TRIPLE P double push-button system of the SDM allows for high miter accuracy and uniform pressure on each part to be joined.

The SDM was designed and built around the user. It is ergonomic designs lets the end user set the angle of rotation giving the appropriate height for the operator. This improves the working environment and reduces health and security risks.

What are similar products on the market?

The assembly tables, clamps and other home-made installations can, of course, be used to make cabinet doors, but these methods are not very effective, and the results are variable according to the pressure applied to the various parts. The businesses using these systems are dependent on the skills of the workers performing the tasks.

There are fast and efficient equipment on the market to assemble cabinet doors, but they operate with nails. Since the trend is to paint rather than varnish or stain, and the paint doesn't provide long-lasting nail head camouflage, people are switching to SDM.

The difference between an SDM and the competition

The SDM components are more robustly built and have fewer parts, resulting in greater durability and performance. This limits maintenance and reduces the risk of breakage, which is crucial for every manufacturer.

How much does a SDM cost and what are the factors that impact the price?

The cost of the SDM will vary significantly based on:

- The type of joints that will be used. Whether the company needs to assemble doors with 90° joints, mortise and tenon joints or miter joints, the equipment will need to be modified and the costs will fluctuate.

- The size of the doors to be produced. The equipment capacity will impact the final price. It may be possible to purchase a non-standard SDM to accommodate doors of other dimensions. For instance, the 48" x 96" SDM is a very popular choice for our customers for exterior doors or up to 10' long for kitchen units.

The basic model starts at $4,000 but the price can vary depending on the three basic features and can go up to $10,000 for the "all-inclusive" model.

Is there an installation fee?

The customer can install the equipment at the reception by following the simple procedure available on our website. A simple compressed air connection is all that is required.

Is there a shipping charge?

Yes.

Let's see the SDM door clamp in action with Tim Rose!

Conclusion

If you have a need to design cabinet doors, the Door Master series of equipment will increase the speed of your production and improve the quality of the finished product, no matter what volume you need to produce.

You are sure to get a good return on your investment by saving time and energy in door production, allowing you to either increase your production capacity or focus on other tasks needed to grow the business.

The SDM cabinet door presses are robust, durable, and user-friendly equipment. It requires very little maintenance and handling. They were designed specifically to meet your needs. They are the result of our years of experience in helping businesses like yours through their various growth and optimization challenges.

What's next?

Contact the Doucet sales team to discuss your needs and confirm your potential productivity gains. Doucet is a North American leader in the design, manufacturing, and integration of advanced solutions for secondary wood processing companies.

All our products are designed and manufactured to fit your environment. Contact us for more information!

For your convenience we have 3 ways to contact us:

- Complete the “Request a quote” form online.

- Via Email: info@doucetinc.com

- Or call us at: 1-866-673-8876