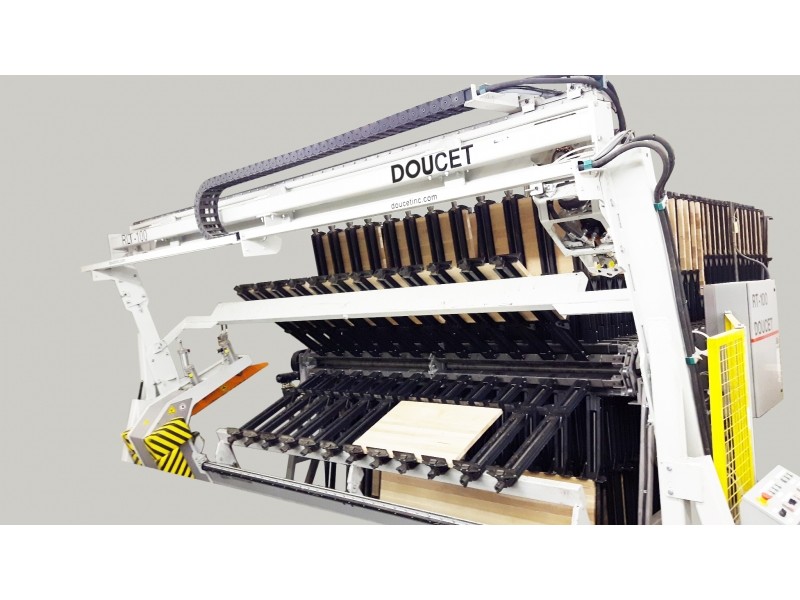

RLT100 - Twin Robotic Operator

The Twin Robotic Operator RLT100 is made for tightening and loosening high volume of glued panels.

RLT100 Double Actuated Flattener

RLT100 Double Actuated Flattener

RLT100 Loosener Motor

RLT100 Loosener Motor

RLT100 Aligned Laser Sensor

RLT100 Aligned Laser Sensor