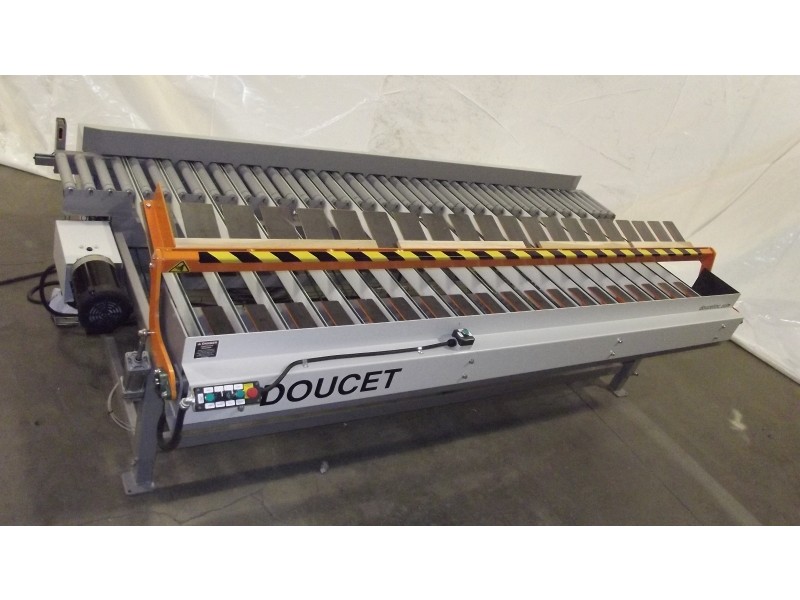

EZYPAC 100 Ergonomic Nesting System by Doucet Machineries Inc.

EZYPAC 100 Ergonomic Nesting System: speeding-up packaging by minimizing unproductive motions.